Hi

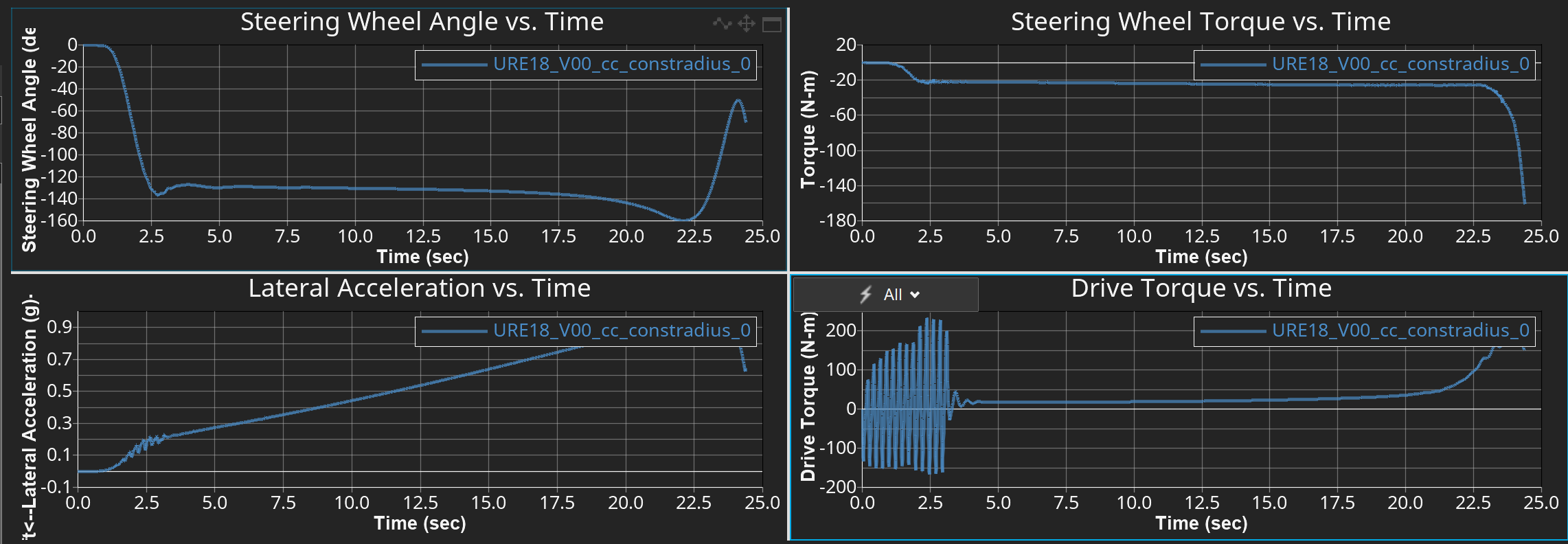

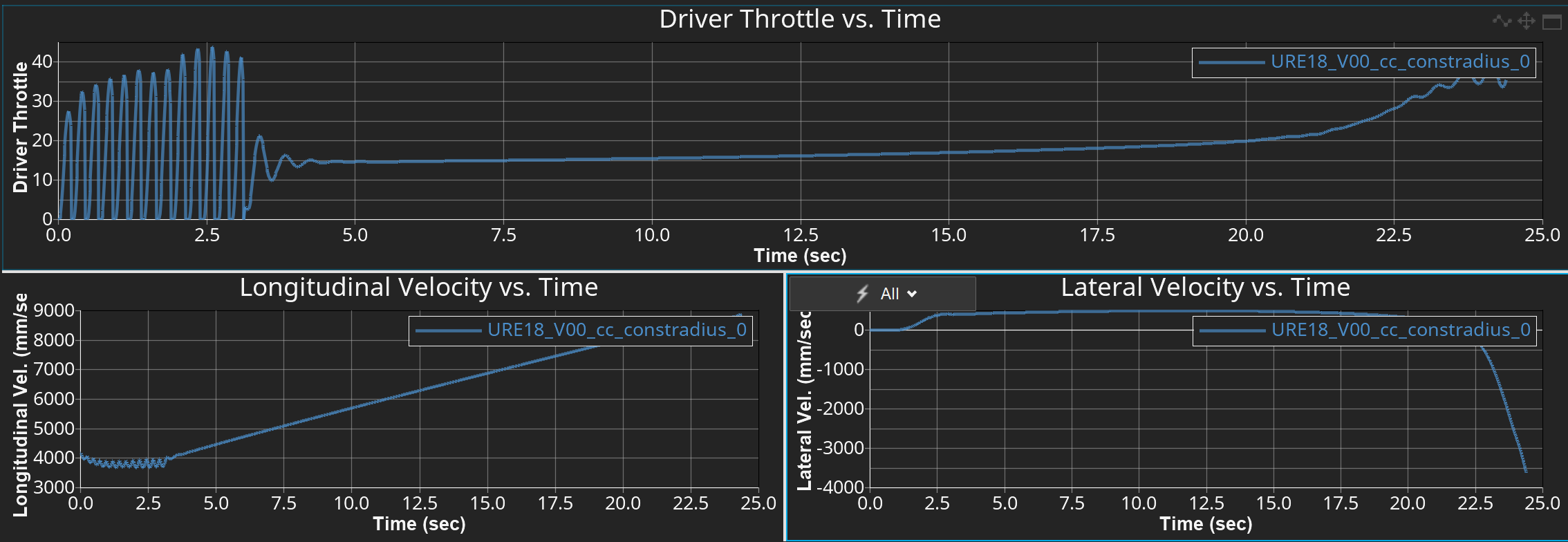

I have modified a full vehicule with driver to the car we are trying to simulate. Everything works fine until I change the weight of the electric motors, the torque becomes unstable. The simulated event is constant radius, this only happens on the straight part of the constant circle; once the turn starts, the torque stays stable. This disturbance can also be seen in the force acting on the suspension. Any clue as to why this is happening?

Thanks in advance

Bollow the plots I get of the event