Here is our project:

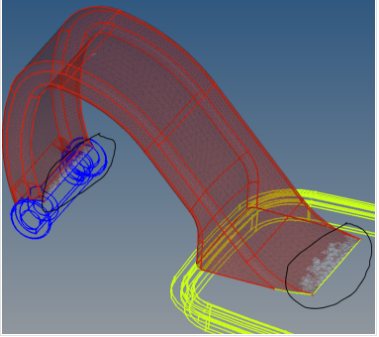

We wanna do some topology optimization on a feul door component as you can see in attached figure:

We used two surfaces to trim the oringinal solid part into 3 separate components. We wanna keep the blue and yellow unchanged and minize the weight of the red part while still satisfy some strength requirement.

We used tetra element and mesh the component autoly. As you can see, there are some low quality, flat and squeezed elements (white ones in the black circle) near the intersection area between design and undesign space. After I set up everything (Boundary condition, Force, Optimization settings), and click optistruct, the system operator tell me that we failed in element quality check. I think it perhaps has sth to do with the model geometry.

Here is the problem:

Now that we cannot change the model geometry, is there any better mesh strategy to obtain a better mesh to pass the element quality check? (I know that auto mesh is definetly not an idea choice) I tried auto tetra mesh with a smaller element size and it didn't work.

Since I'm a beginner and have to learn everything from the very beginning, can you also provide me some basic tutorial links? (Video tutorial will make life much eaiser lol)

<?xml version="1.0" encoding="UTF-8"?>