Product = GENESIS

In this blog we illustrate the design of a simple stamped steel bracket optimized for minimum mass and minimum stress using shape optimization with GENESIS structural optimization software and its gui Design Studio. The fea model is made with shell elements. GENESIS’s shape optimization can also be applied to solid element models, bars, rods, etc.

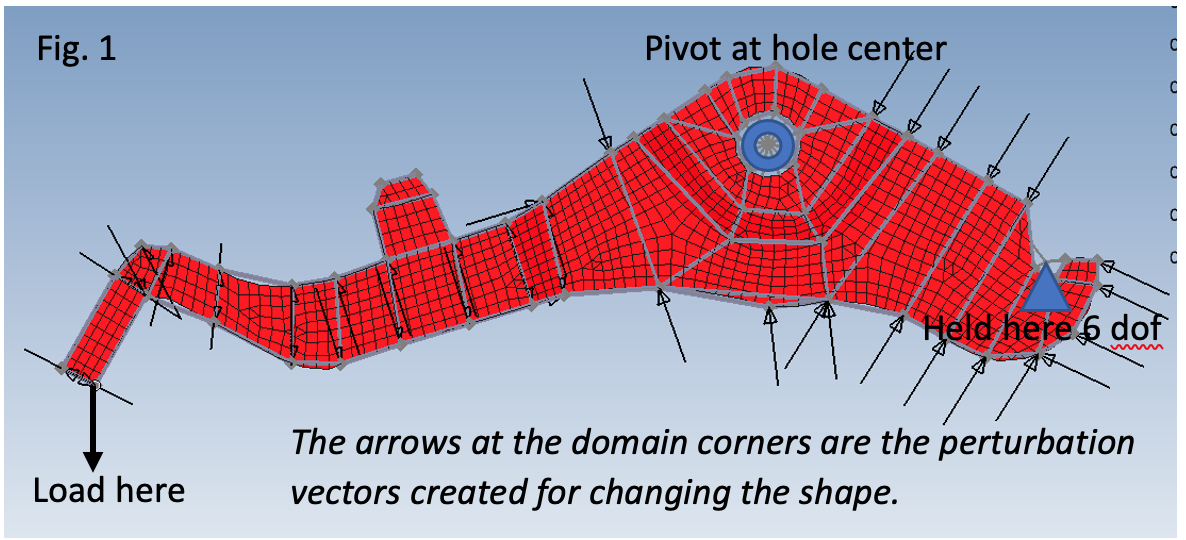

Custom created quadrilateral and triangular domains (a.k.a. morphing boxes) were built in order to closely surround the part. Domains can also be larger than the part or assembly and do not need to trace closely to the profile as in this example. Perturbation vectors are used to push domain corners to expand or contract the shape’s profile during the optimization. These perturbation vectors are assigned a distance to push or pull up to that distance individually but the maximum allowed distance can also be controlled globally in cases where some of the individual numbers result in grid location movements that are not smooth.

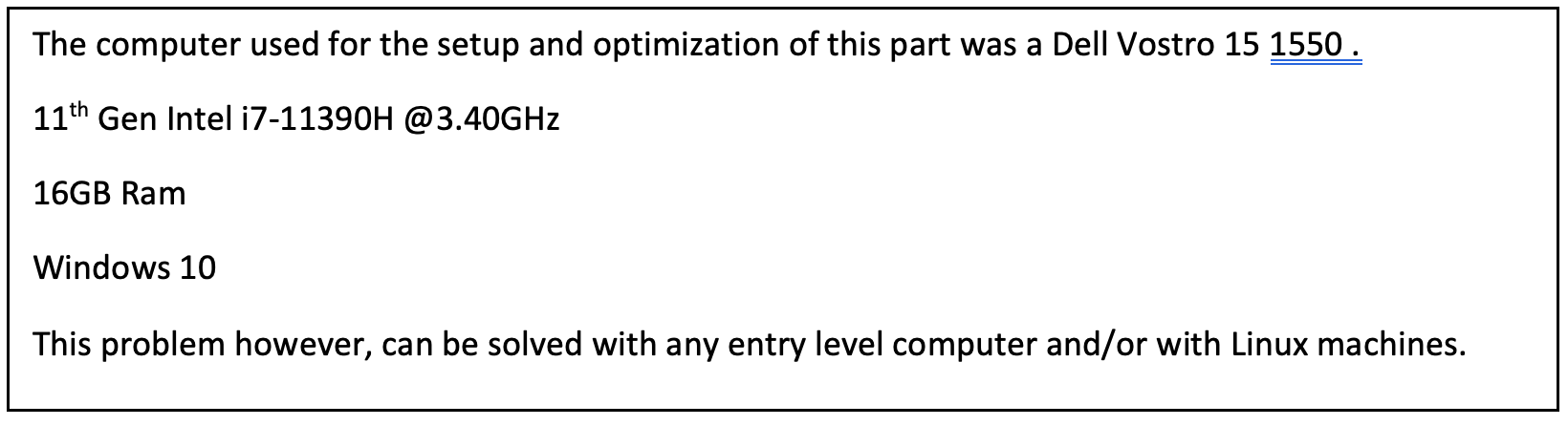

The FEA setup was simple with a pivot at the hole center, loading on the left and held in position on the right, as shown in Fig.1. Boundary conditions such as these are easy to create in Design Studio. The total setup time for boundary conditions, shape domains and shape perturbations, was approximately 2 hrs. for this part.

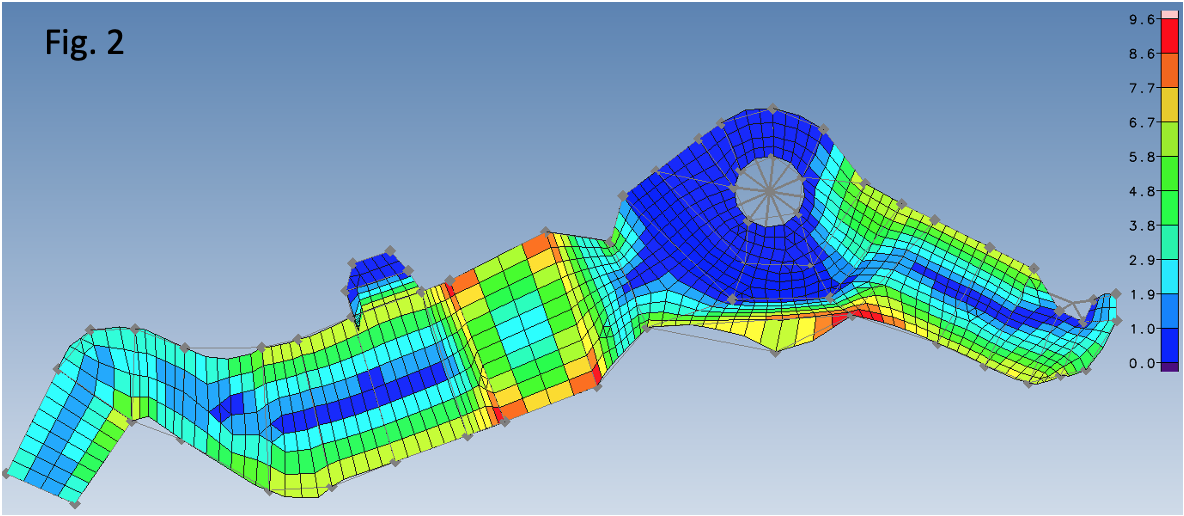

Fig. 2 shows the shape perturbations preview feature which helps the user understand the overall shape change direction and magnitude before the optimization is initiated.

Fig. 3 shows the FEA on the original shape which had a maximum of 373 MPa Von Mises stress with a mass of 0.04046 kg. The solver is part of the GENESIS code. No outside solver is needed. GENESIS ties together the FEA analysis with the optimization in one self-contained package. Values in pink are values that exceed the allowable value of 300 MPa.

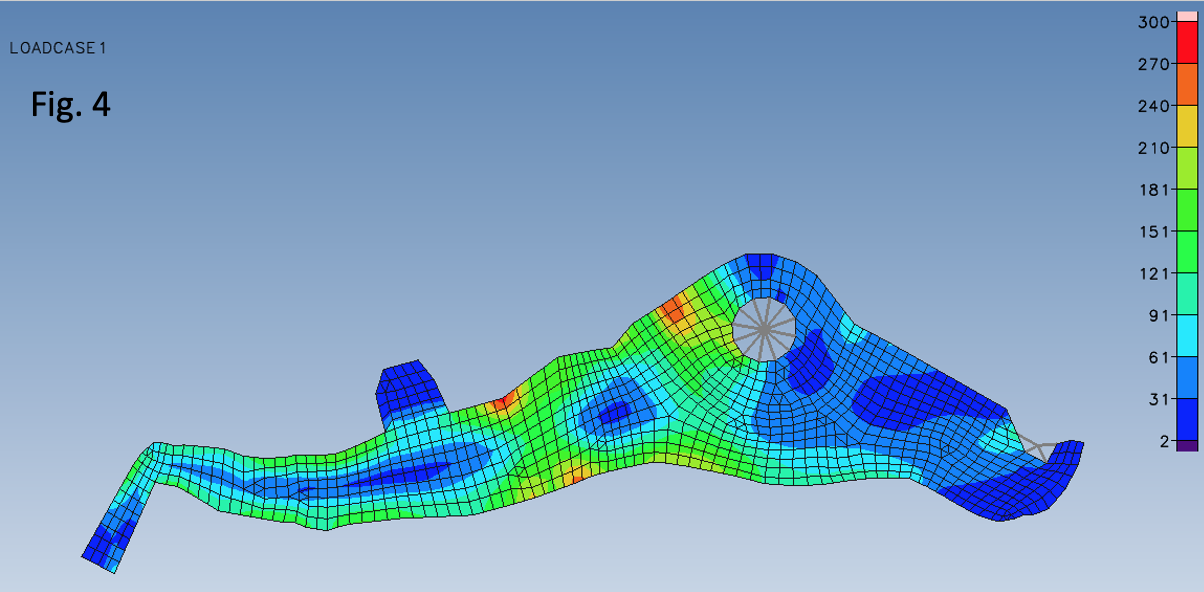

Fig. 4 shows the result of the first optimization which allowed up to 3mm of perturbation movement. This run gave a maximum stress of 289 MPa and a mass of 0.03691 kg. This is a 22.5% reduction in stress and an 8.8% reduction in mass. The total run time for the FEA/optimization was around 1 minute and took 9 design cycles for GENESIS to complete the optimization

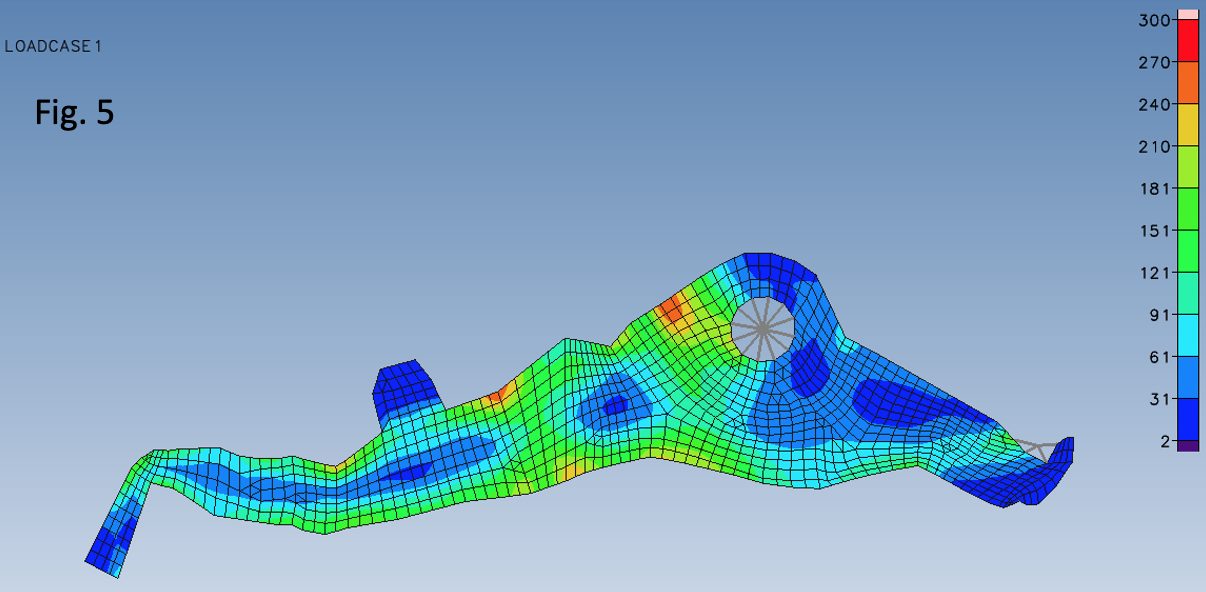

Fig. 5 shows the second optimization which allowed up to 5mm of perturbation movement. This gave a stress of 274 MPa and a mass of 0.03445 kg. This is a 26.5% reduction in stress, and a 14.9% reduction in mass. The total run time for the optimization was also around 1 minute and took 10 design cycles to complete the process.

In summary, while this is a very simple part of a larger mechanism, there was still room for improvement, and quite a bit of improvement was realized with 26.5% reduction in stress and 14.9% less mass. The setup for the optimization was relatively quick, and feasible answers were obtained in only about a minute of runtime. The only inputs required for Design Studio were the bracket’s shell mesh. The rigids and boundary conditions were created in Design Studio. The new geometry shape can be output as an .stl or .igs file to be shared with a CAD program.

Connect with us now for complimentary webinars and evaluation software.

Our engineering team can work with you to conduct a Test Case showing how how Genesis will improve your designs, processes and your overall business