Hi all

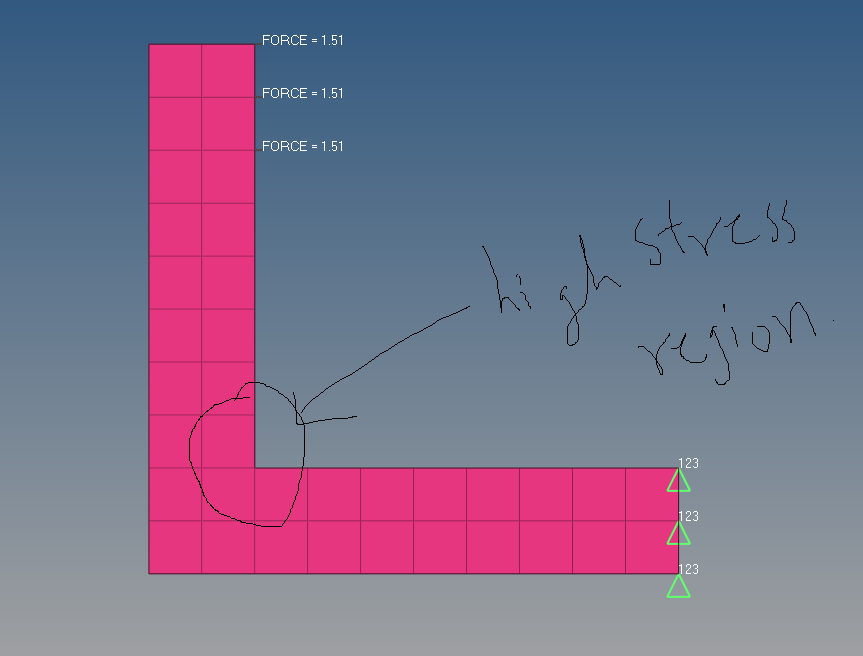

I am doing a structural analysis where stresses are high at the sharp corners .

can any one suggest me how can i decide the element size in this case.(as the stresses goes on increasing with the fine meshing )

suppose if i want put a fillet at the sharp corner,i even need to mesh it fine to cover the fillet.

please help me in this.(my problem is similar to the attached)

I tried with different szes but with decrease in element size the stress going ion increased,putting a fillet driving me to mesh it fine to cover the fillet .

please help me in this regard.

<?xml version="1.0" encoding="UTF-8"?>