Hi,

I recently mesh an aluminium tube with 3mm square shell element and applied a time step ('control_timestep') with parameter of TSSFAC 0.9 and DT2MS -0.05. So the calculated time step is 0.045ms. (unit system: Gpa, mm, ms, kg) As soon as I assigned crashing velocity as 150mm/s, the simulation went well and yet a reasonable result.

Q1: according to the CFL condition, the time step can be calculated by the formula t=L/(sqrt(E/p*(1-v^2))). But if I use this formula, the time step is 0.55e-3ms which much much smaller than 0.045ms. Since the calculation gives the minimum time step, how is it possible to give me the correct simulation result by using a bigger one?

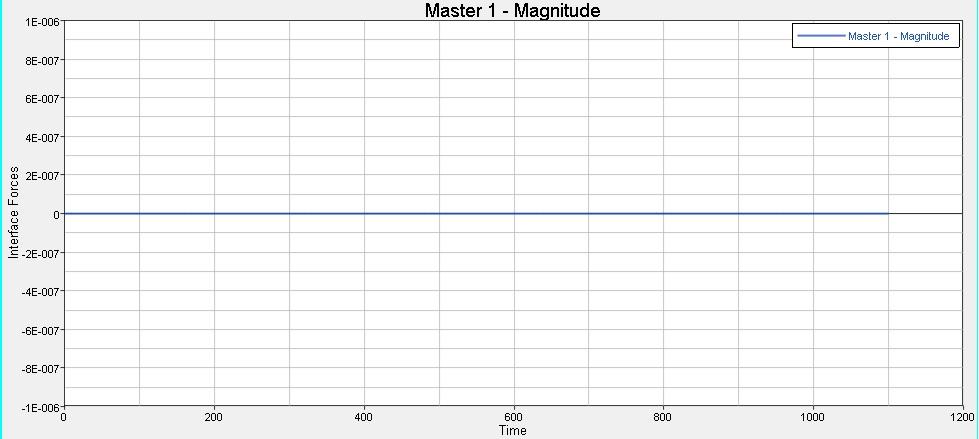

Q2: when I assigned another speed 0.33mm/s, I just got a straight line (see attachment) over the force-time curve. What should I put in the control_timestep card?

Please help.

Many thanks.

<?xml version="1.0" encoding="UTF-8"?>