Dear all,

I am want to simulate a tensile test experiment. Although I have simulated with the help of a video on youtube, but in my simulation I am getting some unusual results which generally not happened in my previous attempts.

I had attached the .hm and .h3d file. I am using HyperWorks v12.0 for my analysis.

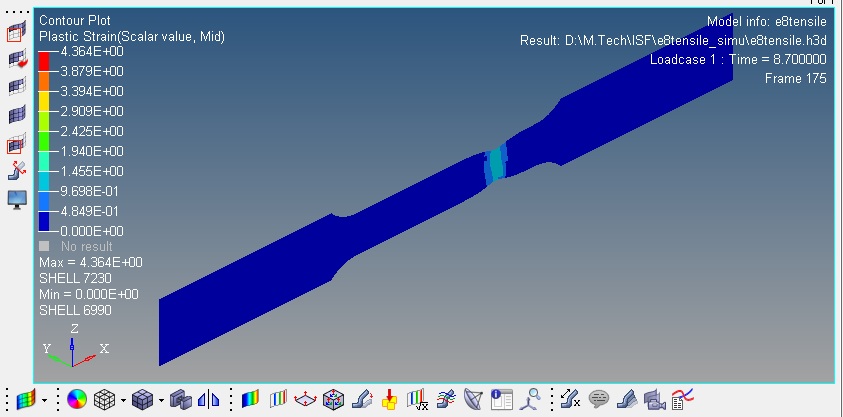

Initially it shows good results because in actual experiments my specimen have fractured in same area where it shows in simulation.

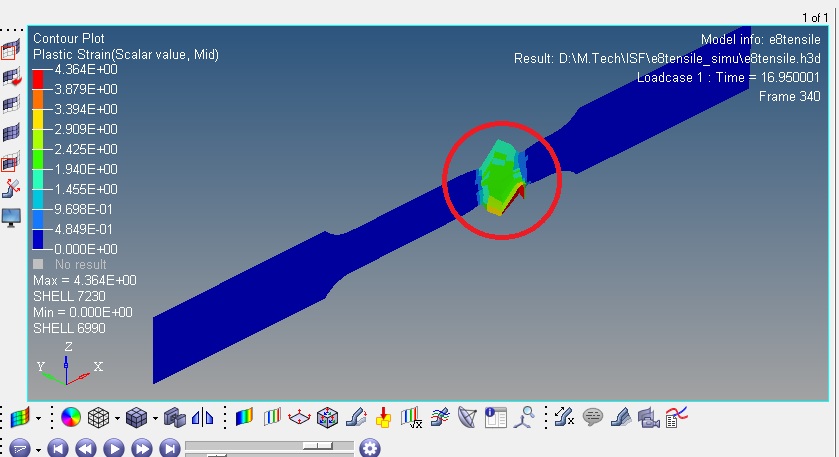

But after some time it show very unusual deformation.

Please check my model and suggest me if I have done some thing wrong in this model.

Unable to find an attachment - read this blog