Hi

I'm working on my thesis and I'd like to have your comments regarding meshing.

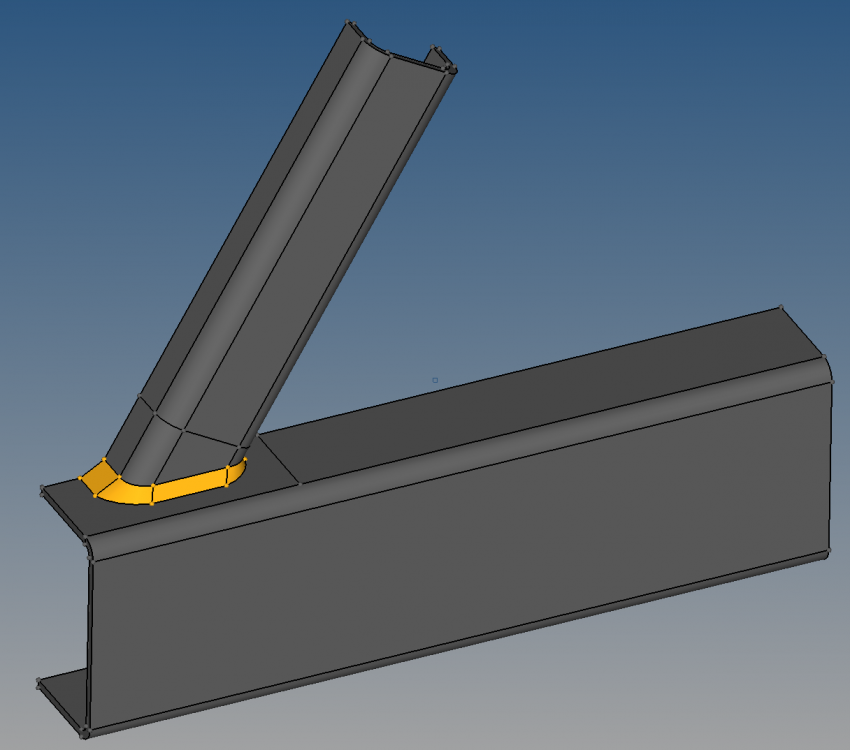

- the part to be analyzed is a joint from steel truss (1/4 modelled)

- Abaqus solver

- I want to use as many brick elements as possible (C3D8R)

Simplest solution would be to use shell elements but I want to model the welds too. Welds (orange color) will have different material properties than other pats.

What is the best way to 'slice up' this kind of model and what's the best way to mesh it?

Link for files: https://www.dropbox.com/sh/q7fkfir1ayyxp2i/AABY0WVKMD8gpyfhcA3-6zdBa?dl=0

BR

Ari

<?xml version="1.0" encoding="UTF-8"?>