Hi there,

my problem is as followes: i built up a squarish composite plate (carbon) with orthotropic material property. I edited the laminate with 'symmetric' option to realize the orthotropic

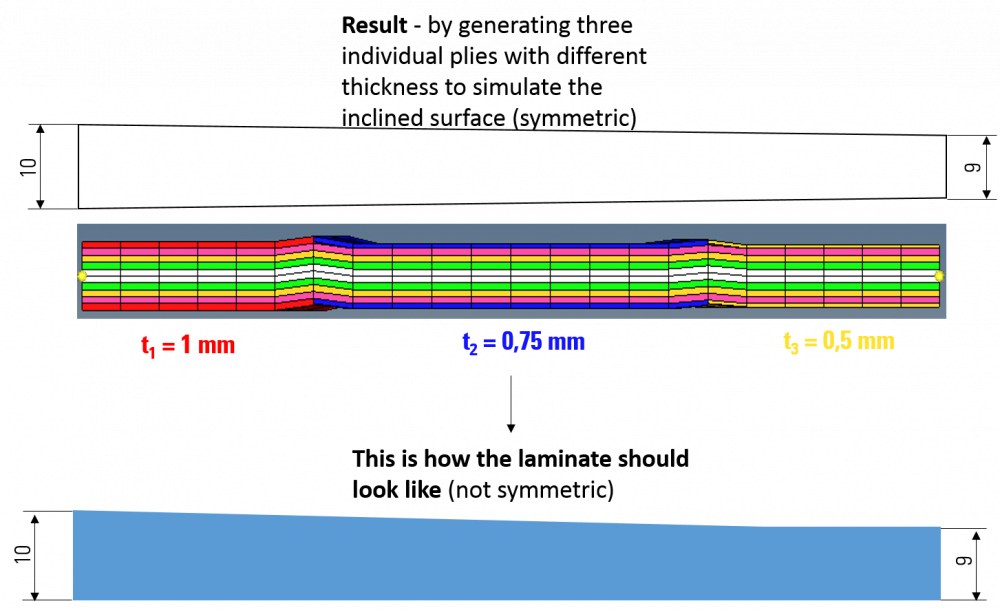

material behave. Now my problem is that I want to check the material behave varying ply direction and ply thickness. So the plate should obtain 10 mm height on the left edge and 9 mm on the right edge to simulate an angular load initiation, Now the symmetric laminate option causes a result which I dont want to realize (see attachment). Can you tell me how to realize that? Maybe with shell to solid conversion (how do i get there?)?

Regards

<?xml version="1.0" encoding="UTF-8"?>