Hello!

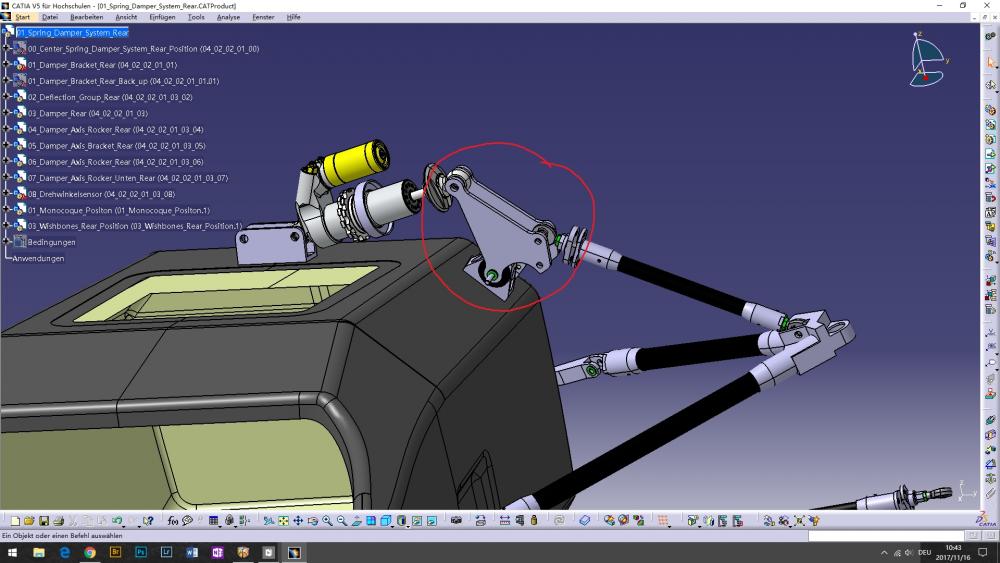

I have a rocker which should be optimized. I added force and joints, but no matter I try maximize stiffness or minimum mass (there is always 'design violations' with the safety factor) the results are not so good.

The picture shows how the rocker works.

The .stmod file is also attached.

Thank you very much!

Best Regards

<?xml version="1.0" encoding="UTF-8"?>

Unable to find an attachment - read this blog