Hello,

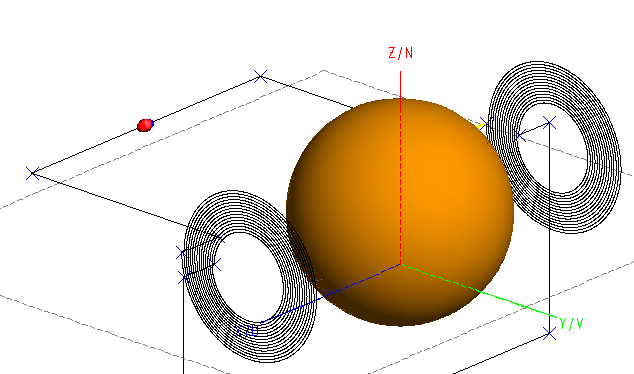

My FEKO model consists of two coils placed diametericaly opposite on either sides of hollow sphere.

Coils are perfect electrical conductors, and hollow sphere is free space. Excitation is done with 1V 60Hz source.

I have following questions:

1. Often I come across the term, 'Electrical size'. It seems electrical size, geometrical size and mesh size are all related to each other. In this regard,

a. What does FEKO mean by 'Electrical size' of problem?

b. How does 'Electrical size' affect geometrical size and mesh size ?

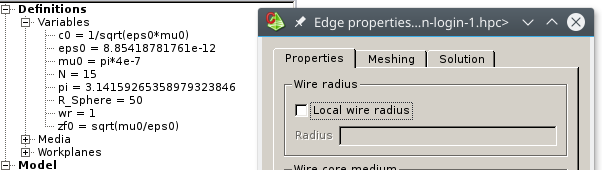

2. In my model, all wires have radius of 'wr = 1mm'. As shown below, an option in 'Edge properties' could specify 'Local wire radius'.

What is 'Local wire radius', and when is it used?

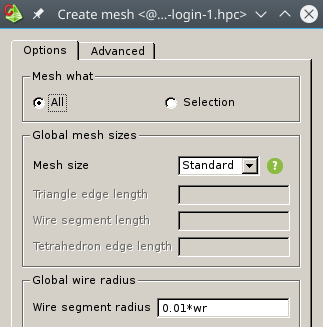

3. While meshing, there is another option to specify 'Global wire radius'.

a. How is 'Global wire radius' different from 'Local wire radius'?

b. Since 'Mesh size' is 'Standard', does 'Global wire radius' still affect mesh?

Regards,

FieldForcer