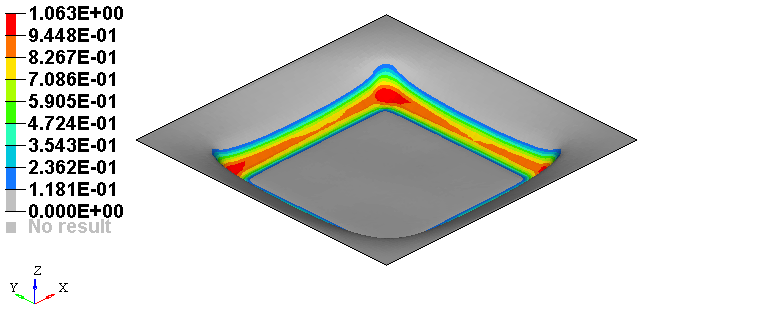

I have simulated incremental sheet forming process in Hyperworks software and now I am analyzing the results.

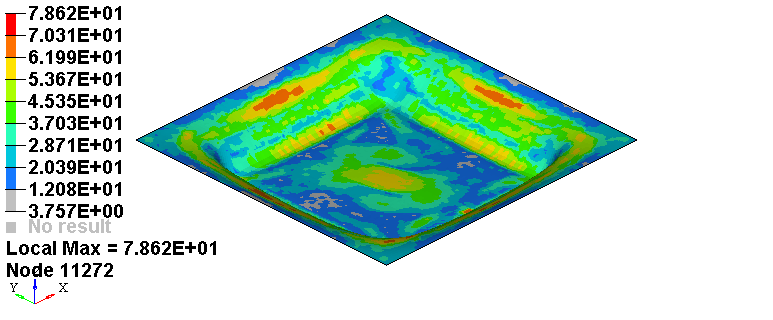

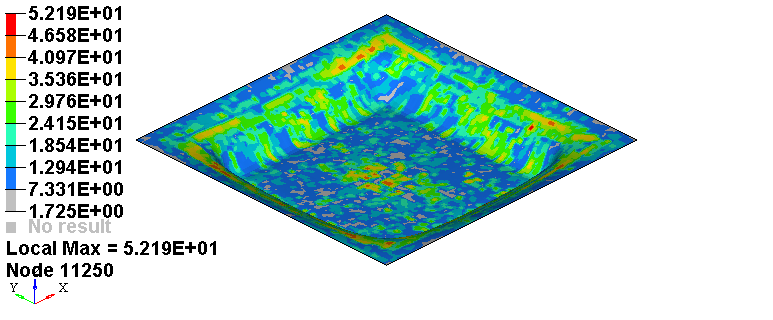

1. The issue is that the undeformed portion of the sheet is also showing significant amount of von Mises stress and strain values. Which is absolutely impossible. How come the center undeformed portion of the component is experiencing effective stress and strain. However, there is no plastic strain in that area. Kindly, go through the attached images.

2. Secondly, Plastic strain distribution is correct but it does not sink with the von Mises strain results. What is the difference between the two.

3. Is the values of von Mises strain are in absolute terms or in percentage?

<?xml version="1.0" encoding="UTF-8"?>

<?xml version="1.0" encoding="UTF-8"?>

<?xml version="1.0" encoding="UTF-8"?>