Hello guys,

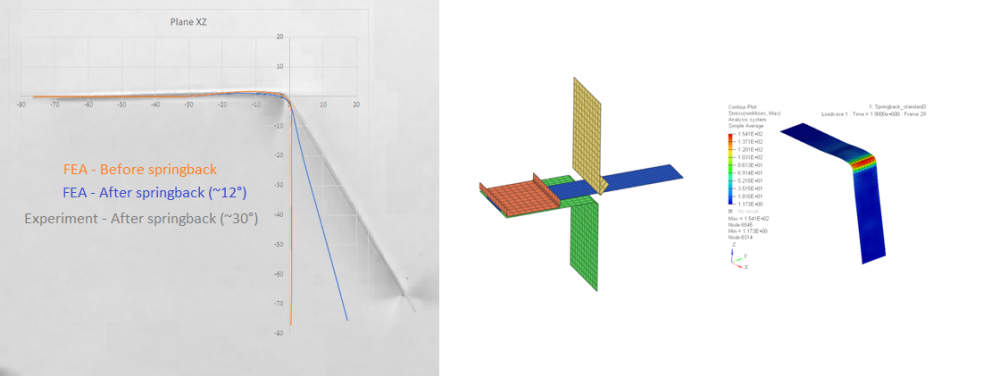

I am trying to validate a springback model to be used in a more complex forming simulation. For now I am performing some 90º bend experiment on a lab and trying to compare the results with my model. Unfortunately I am getting more than 25% error, while I see on literature that the result for simple cases like that should be much better. What am I doing wrong? I already tried a bunch of tips and different parameters. Please, find the results and the model attached. Could someone please take a look and give me some hints?

Is there a way to 'turn off' or 'reduce' dynamic/impact effects? I could notice the sheet body bouncing and waving. I am not sure if it also happens in reality but our eyes can't capture.

Thank you in advance.

<?xml version="1.0" encoding="UTF-8"?>

Unable to find an attachment - read this blog