Hi all,

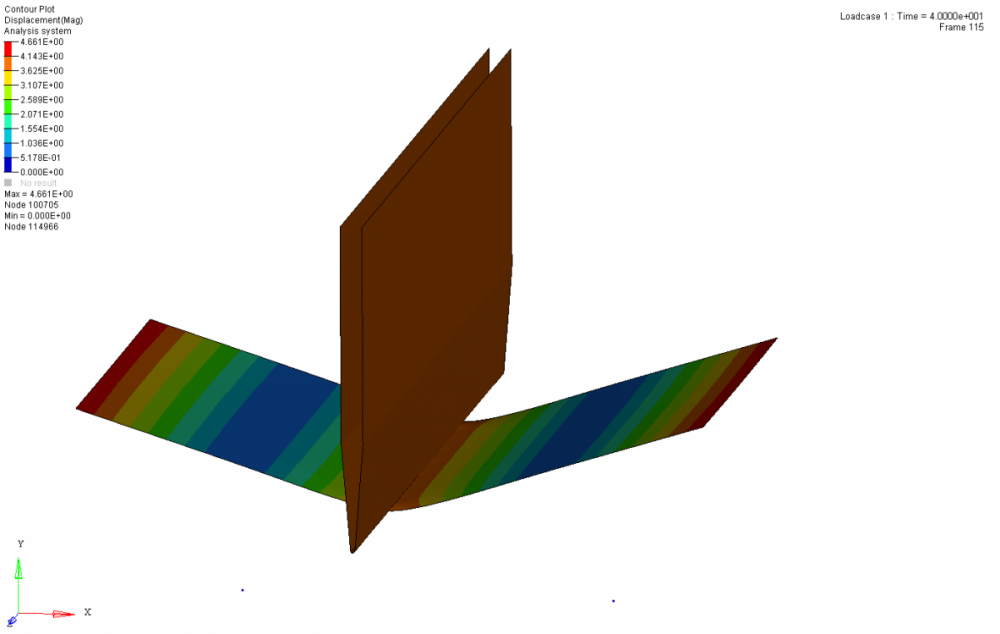

i am simulating a three point bending test of a flat sheet sample (two rolls for support and a sharp edged stamp).

<?xml version="1.0" encoding="UTF-8"?>

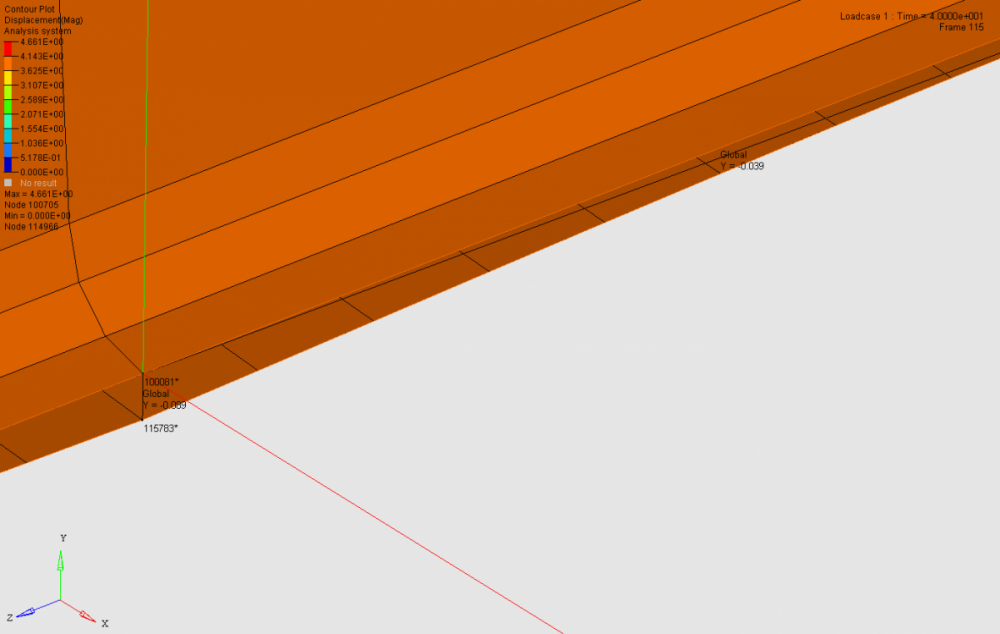

For contact between stamp and specimen i use /INTER/TYPE7 with constant GAP=0.09 with both Parts being master and slave at the same time.

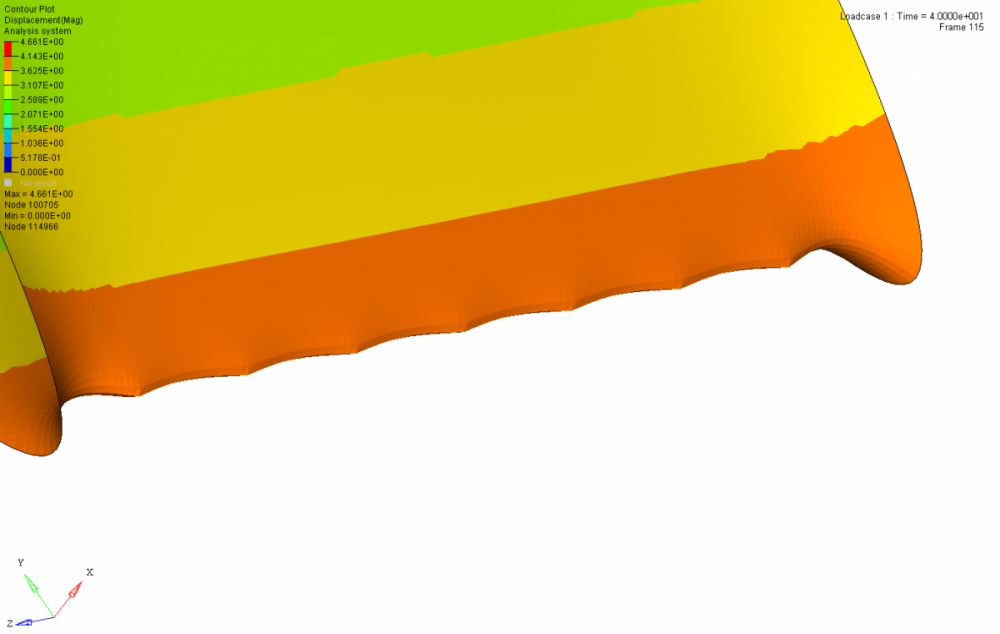

However i discovered, that i get penetrations through the contact gap by up to 60%, see pictures (Detail_02 is enlarged with factor 10):

<?xml version="1.0" encoding="UTF-8"?>

<?xml version="1.0" encoding="UTF-8"?>

It seems, that only on the nodes locations of the stamp part the gap is kept, between those nodes there is penetration. Why is this happening? The gap should be kept also between the stamp parts nodes, because there is a master segment on the stamp surface and a slave node on the sheet part...