Challenge

Assessing The Package Space In an Assembled Suspension Model

PREFACE

Physical vehicle testing is resource intensive. Vehicle modeling and simulation provide an efficient alternative which can be implemented earlier in the design cycle to understand a vehicle’s dynamics. Multibody dynamics software such as Altair MotionSolve allows users to set up and analyze a wide range of dynamic systems, including vehicles. Altair’s MotionSolve allows the simulation of a large selection of vehicle events to analyze vehicle performance parameters. Results can be used to refine vehicle design and improve occupant comfort.

INTRODUCTION

Wheeled vehicles typically have suspension parts that move relative to their frame/body structure, and therefore require packaging studies to ensure adequate inter-component clearances. Vehicles which have fenders that enclose the tires to form a "wheel well" for protection from dirt and road debris, require additional design checks. This is to ensure adequate clearance between the tire and body under all operating conditions, specifically when the suspension is fully compressed and/or steering is at full lock. Such checks have usually been performed in the CAD environment, and some automotive OEMs even have proprietary in-house tools to enable it. This type of analysis is called Tire Envelope Analysis.

In this article, we present a methodology and toolset that has been developed using a custom layer on top of the Altair Simulation suite. The advantages over a CAD-based or proprietary approach include:

- High-performance kinematics calculation with dedicated multibody solver, Altair MotionSolve.

- Compliance effects from bushings and structure can be represented for tighter tolerancing.

- Native CAD and graphics translators with accurate, automatic and fast meshing.

- No proprietary workflows or paid plug-ins required.

- Automation of entire workflow is possible for faster turnaround time and/or flatten the learning curve associated with an analyst-grade toolset.

Pre-Requisite

SOFTWARE REQUIREMENTS:

- Operating System: Windows

- HyperMesh (2023.1 or newer)

- Simlab (2023.1 or newer)

- MotionView (2023.1 or newer)

- MotionSolve (2023.1 or newer)

- Workable knowledge of MotionView and Vehicle Modeling preferred.

Model Definition

- Tire_Envelope_Material.zip

Usage/Installation Instructions

Modeling Steps:

- Read in CAD Data into Hypermesh

- Re-group components to represent MBD components

- Export Geometry

- Prepare MBD model with Design Data

- Deactivate graphics that will be replaced

- Import Geometry into model

- Incorporate Tire Envelope Analysis

- Run Solver

- Prepare and view collision sets in HyperView

- Create STL of tire envelope

Post-Requisite

RESULTS

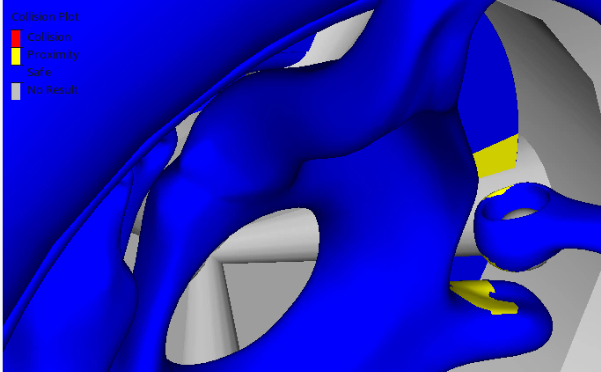

With the rack moving ±80 millimeters and no collisions in HyperView, the analysis seems thorough. However, the proximity warning indicates a close fit between the tierod and wheel hub at full rack travel, suggesting potential for interference.

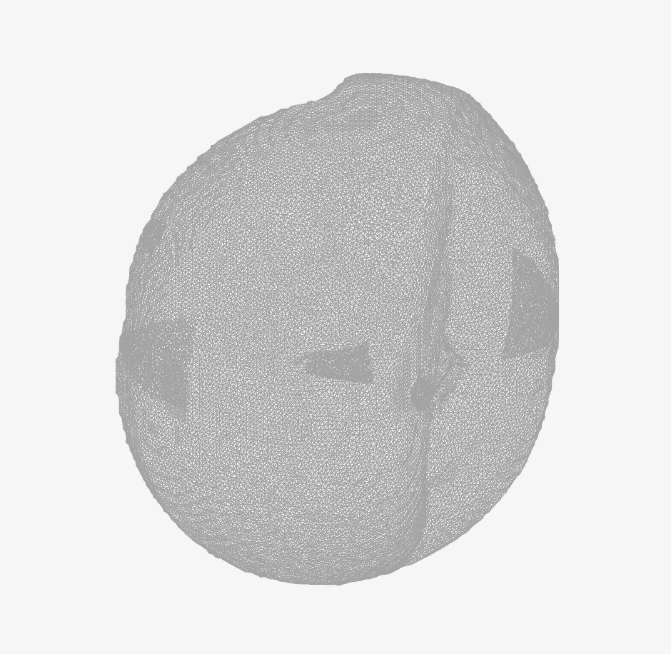

Using a 10-millimeter mesh sizing for both wrapper and surface mesh. Generated the wheel envelope in 35 minutes, which is reasonable for detailed analysis. Consider refining mesh sizing if more detail is needed or optimizing the mesh generation process to reduce time.

Overlaying the geometry with the simulation results allows for visual assessment of package space. Ensure that this visualization is used to identify any critical interference issues or areas for design improvement.

CONCLUSION

The tire envelope analysis effectively demonstrates that by using the envelope workflow instead of manipulating CAD geometry directly, users can benefit from a more accurate and constraint-based representation of the wheel envelope. The envelope workflow offers a robust method for analyzing tire envelopes, ensuring that design predictions are closely aligned with system constraints and enhancing overall design accuracy and efficiency.

For using v2025.1 or greater, please use the updated scripts below.